Edge AI in Manufacturing: Real-Time Automation and Predictive Maintenance for the Next Industrial Leap

- Aug 14, 2025

- 2 min read

Deploying AI at the edge—on-site, intelligent devices—dramatically reduces latency, boosts uptime, and unlocks smarter, safer factory floors in the age of Industry 4.0.

In today's industrial landscape, the ability to act on critical data in real time is no longer optional—it’s essential. Traditional cloud-centric models often introduce latency and dependency on network connectivity, making them unsuitable for split-second decisions on production lines. Edge AI changes that by processing data directly on-site, enabling instantaneous insights and automated responses, and fundamentally redefining how manufacturers operate.

At its core, Edge AI processes data locally—on embedded systems or microcontrollers—so that sensors can immediately analyze vibration, temperature, or pressure readings and act in milliseconds rather than seconds or minutes. This precision isn't theoretical. In one manufacturer’s deployment of Edge AI-based real-time modeling, the results included a 30% reduction in unplanned equipment downtime, 20% savings in repair costs, and 25% faster maintenance scheduling. These gains enable not just cost efficiency but also tangible business resilience.

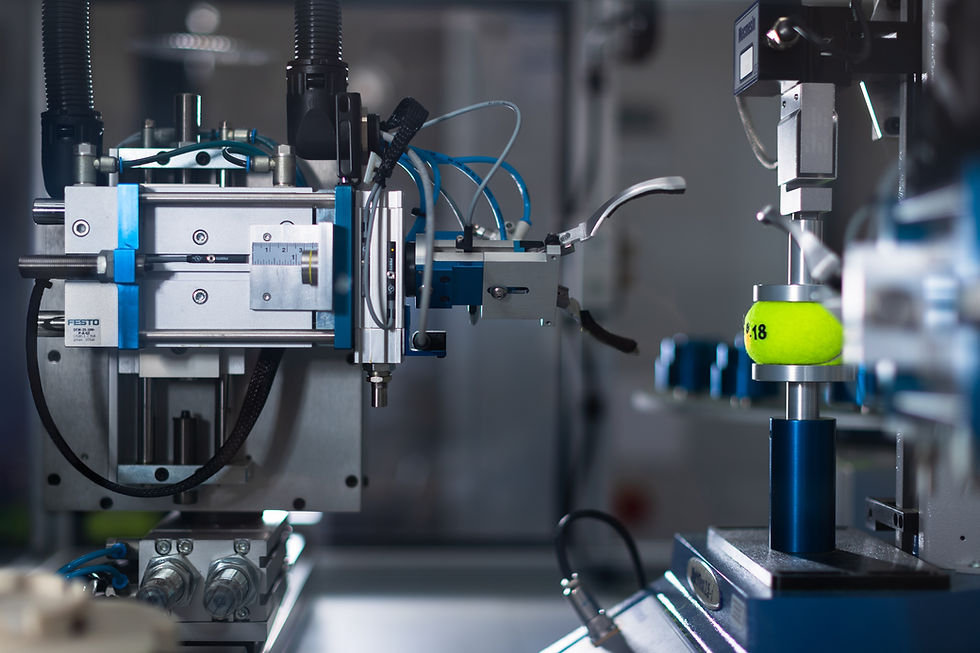

Edge AI's capabilities extend into superior quality control. In PCB (printed circuit board) manufacturing, AI deployed on edge devices replaced slow end-of-line testing. The result was a 30% decrease in end-of-line testing, faster defect detection, and proactive maintenance alerts that minimized unnecessary downtime. In the automotive sector, Edge AI vision systems now scan for microscopic defects—such as weld anomalies—and automatically reroute faulty components, removing the bottleneck of manual inspections.

Beyond productivity, Edge AI brings smart manufacturing closer to the sustainability frontier. In one semiconductor facility, an edge AI energy optimization solution delivered approximately 10% energy savings while reducing carbon emissions. Other industrial deployments, such as those from Fero Labs, have reported average reductions of 35% in manufacturing-related CO₂ emissions.

The backbone of these advancements lies in sensor networks. Manufacturers adopting wireless IoT sensors have seen a 30% reduction in installation costs and double the data acquisition frequency, enabling more responsive and effective Edge AI processing. This means faster insights, lower bandwidth usage, and more intelligent automation overall.

Even in harsh or remote industrial contexts, Edge AI proves invaluable. A TinyML-based predictive maintenance framework for mining machinery demonstrated on-device inference latency as low as 3.33 milliseconds, reduced power consumption by 44%, and maintained classification accuracy above 90%—a vital capability for environments where cloud infrastructure is unreliable.

The benefits are not limited to niche use cases. Ford Motor Company recently implemented two AI-powered quality assurance systems—AiTriz and MAIVS—across hundreds of stations in its factories. These systems detect microscopic misalignments and incorrect part installations in real time, cutting the risk of costly recalls before defects leave the assembly line.

However, unlocking the full potential of Edge AI hinges on one critical factor: AI-ready data. A recent study revealed that more than 60% of manufacturers have yet to adopt AI solutions, largely due to poor data readiness. Without clean, contextualized, and well-integrated data, Edge AI cannot perform to its full capability.

In sum, Edge AI is not just a technological upgrade—it’s a strategic imperative. It empowers manufacturing facilities with real-time automation, predictive maintenance, energy optimization, quality assurance, and resilience in uncertain environments. To fully reap these benefits, companies must build robust data infrastructures that provide the fuel for the intelligent engines of tomorrow.

Sources: